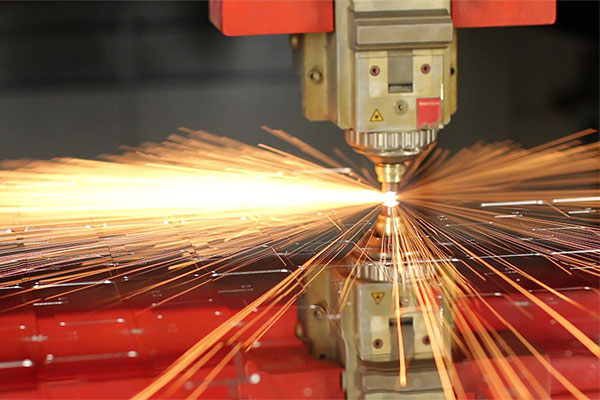

Laser Cutting technology is widely used in the processing of metal and non-metal materials, which can greatly reduce the processing time, reduce the processing cost and improve the quality of the workpiece.The modern laser has become the “sword” of people's fantasy pursuit of “cutting iron like mud”.Laser Cutting is an indispensable equipment in sheet metal processing, and is the most representative procedure in sheet metal processing industry.Dongji sheet metal is a large laser cutting processing plant from Jiangmen area, with 3 large-power laser cutting machines in Jiangmen, specializing in laser cutting Sheet metal processing.

Laser cutting technology is widely used in the processing of metal and non-metal materials, which can greatly reduce the processing time, reduce the processing cost and improve the quality of the workpiece.Laser cutting is realized by using the high power density energy generated by laser focusing.And controlled by computer, through the pulse laser discharge, thus the output controlled repeated high frequency pulse laser, the formation of a certain frequency, pulse width of the beam, the pulse laser beam through the light path transmission and reflection and through the focusing lens group focused on the machining surface, forming a subtle, high energy density, intensity, focal spot near to processing surface, with instantaneous high temperature melting or gasification materials processed.The modern laser has become the “sword” of people's fantasy pursuit of “cutting iron like mud”.Laser cutting is an indispensable equipment in Sheet metal processing, and is the most representative procedure in sheet metal processing industry.Dongji sheet metal is a large laser cutting processing plant from Jiangmen area, with 3 large-power laser cutting machines in Jiangmen, specializing in laser cutting sheet metal processing.

Each high energy laser pulse sputtered a small hole on the surface of the object in an instant. Under the control of the computer, the laser machining head and the processed material hit points in continuous relative motion according to the pre-drawn figure, so that the object can be processed into the desired shape.When cutting externally, a stream of gas coaxial with the beam is ejected from the cutting head and the melted or vaporized material is blown out from the bottom of the cut (note: if there is a thermal effect between the gas blown out and the material to be cut, the reaction will provide additional energy for cutting;The airflow also has the function of cooling the cut surface, reducing the heat affected area and keeping the focusing mirror free from contamination.Compared with the traditional plate processing method, laser cutting has the advantages of high cutting quality (narrow incision width, small heat affected area, smooth incision), high cutting speed, high flexibility (can cut any shape at will), wide material adaptability and so on.

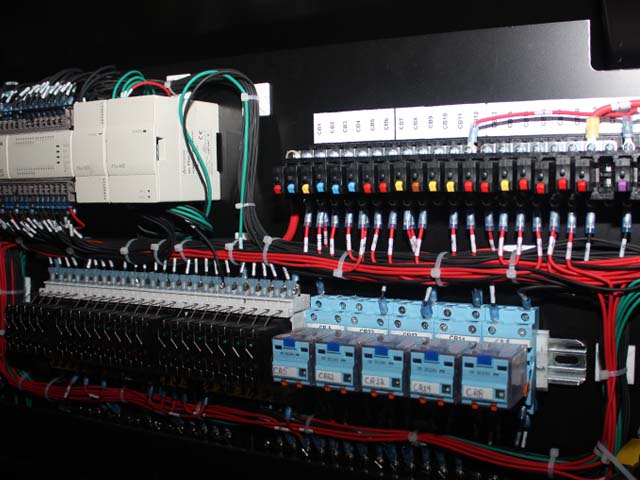

Production equipment

Our company owns a Bystronic Di Neng 3000W laser cutting machine, which can cut medium and thick plates without using a mold, and can cut steel plates of any shape, with a smooth laser cutting surface.

Laser Cutting Machine

Quantity:3 pc

· Power 3000w

· Processing accuracy 0.1mm

· Processing speed 20 m/min