3D printing is already a familiar technology, but for users of major metal 3D printers, cleaning up prints is definitely one of the most headaches, because there is usually a lot of metal powder left on the printer. If these powders are not removed, it will definitely affect the use of the print, but it is time-consuming and labor-intensive to do it manually. In addition, if it is simply removed and not recycled, it will cause waste, and you must know that metal powder is very expensive. However, 3D printing powder recycling machines can completely solve these problems.

Generally speaking, metal 3D printing is different from polymer material 3D printing, and the most important difference is waste. But this waste is necessary waste, because usually only a small fraction of the powder can be converted into metal parts, and the rest of the powder is not used. This is because the powder covers the entire print bed before melting. So, how to save metal 3D printing powder? For example, relatively large parts can be printed, maximizing the use of powder and reducing waste. Unprinted powder can also be reused, but general equipment does not have such a recycling function. The 3D printing powder recycling machine can remove the powder remaining on the printed parts through rotation and vibration and then recycle them, thus avoiding material waste to the greatest extent and saving costs for users.

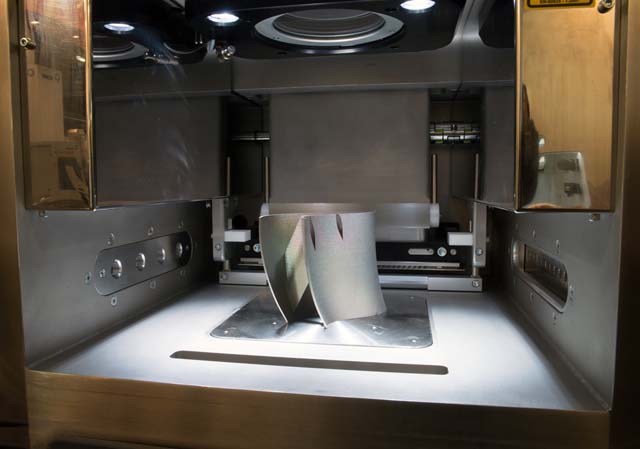

The 3D printing powder recycler's swivel runs on two axes and has an auto-opening top (for loading heavier prints. The 3D printing powder recycler's swivel runs on a single axis. Actual work , the machine's table holds the print, then rotates in a predetermined path while applying vibrations of different frequencies to remove any residual powder from the part.

Finally, the powder is recycled into special containers or reused through an external sieving device. In recent years, the capabilities of metal 3D printers have been rapidly improving, and the range of applications has continued to expand. Studies have shown that more than 70% of the total cost of 3D printing a metal part comes from the front and rear processes. ” The 3D printing powder recycling machine completely solves the problem of resource waste and reduces the printing cost.